Products

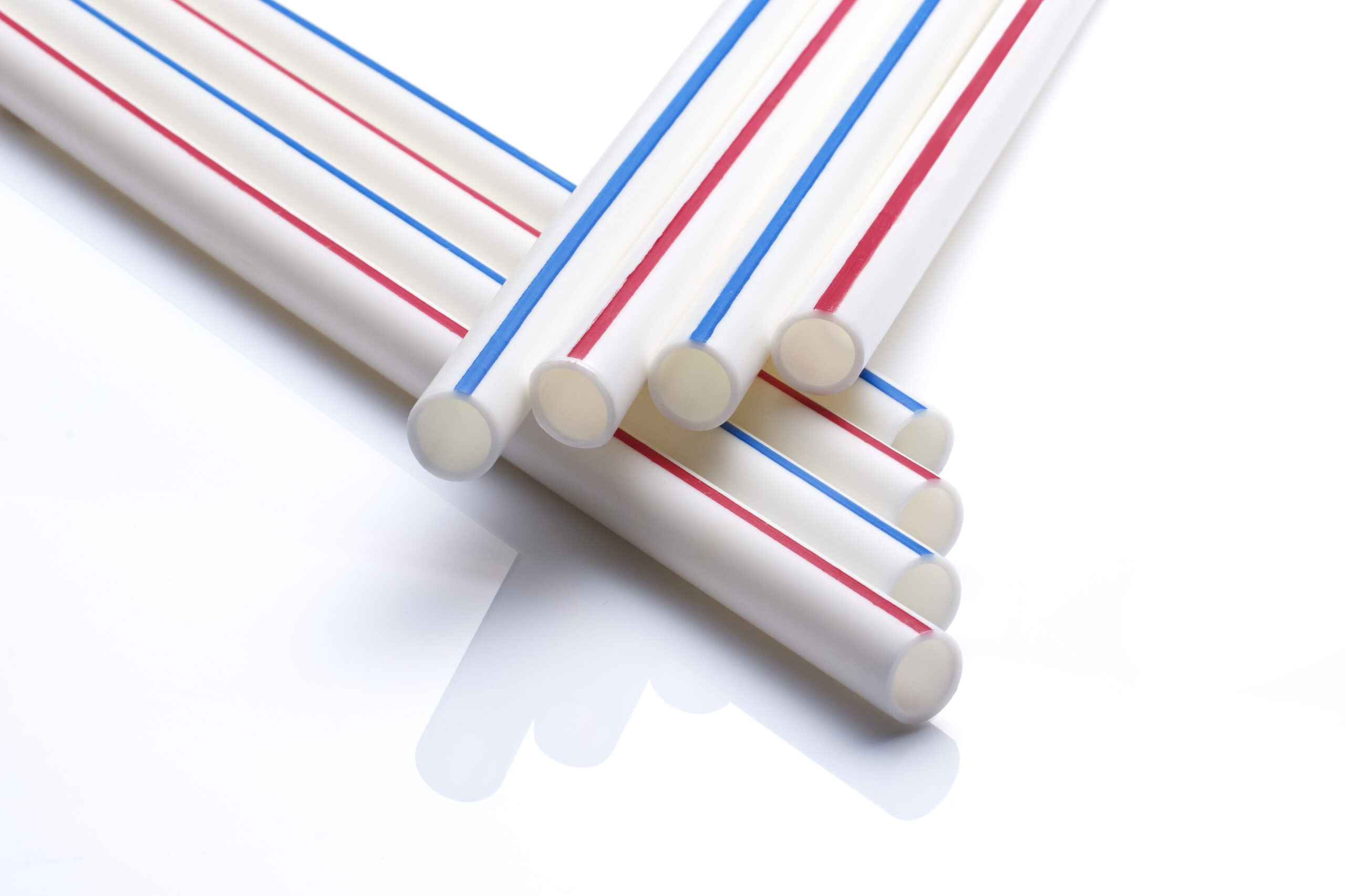

PEX-a PIPE

We manufacture PEX-a pipes with or without EVOH oxygen barrier (3 and 5 layers) according to the European regulation EN 1264-4 by adding a ethyl-vinyl alcohol copolymer layer that prevents the permeability of the tube to oxygen diffusion, eliminating the problem of oxygen supply to the water flow and corrosion in the metal elements of the installation extending its lifetime.

We produce Pex-A achieving an average >70% of crosslinking degree during the manufacturing process (higher degree does not mean better product), our technology does not need further treatments and is the only process that guarantees an excellent crosslinking uniformity along the pipe (maximum difference of 0.5%) providing major traction and pressure resistance, better stability under extreme temperature conditions, more flexibility and chemical resistance to solvents, oils and water without incrustations, corrosion or aging.

Our PEX-a crosslinked polyethylene pipe is manufactured using the Organic Peroxide method, having as a result the highest quality PEX pipes on the market and being Certified by the main Worldwide Institutes (AENOR, SKZ, CSTB, IIP,NSF, KOMO, ASTM) complying with the UNE-EN ISO 15875 European regulations and ISO 9001.

Advantages:

Easy Installation

No welding or mechanization required as the fittings system gives

simplicity and optimizes the costs.

Flexibility

Higher flexibility than other PEX pipes. Can be easily bent and curved in

cold without special tooling, saving unions and installation time.

Temperature resistance

Allowing temperatures up to 95°C and even 110°C for short periods.

Pressure resistance

The high crosslinking degree provides more than 50 years lifetime

durability.

Resistant to corrosion

Suitable for corrosive fluids transportation.

Minimal pressure losses

Much lower roughness than metallic pipes reducing energetic consumption

and allowing a higher flow with the same internal pipe diameter.

No deposits

Layers very resistant to calcium, dirt and substances derived from

galvanic corrosion.

Lightness

It weights 7 times less than copper and 13 times less than iron on

equivalent diameters.

Excellent sanitary conditions

It does not modify the organoleptic characteristics of drinking water and

the corrosion absence avoid proliferation of bacteria.

Thermal, Electrical and Noise Insulator

Providing energy savings by reducing heat losses.

Frost resistance

It prevents condensation, reducing the freezing process.

Suitable for seismic zones

Because of its elasticity can absorb higher stress than metal pipes.

Thermal memory

Recovering the original shape when hot air is applied allowing to be

repaired.

Applications

- Plumbing installations.

- Underfloor heating systems

- Radiator heating installations

- Air conditioning installations

- Industrial installations (compressed air system, transport of toxic or

corrosive fluids …) - Ice/snow melting systems for public buildings or particulars

- Livestock facilities

DOWNLOAD PE-Xa Product Characteristics

PE-RT PIPE

We include PE-RT pipes (Polyethylene of High Temperature resistance) with excellent long-term hydrostatic strength and flexibility in order to provide the most extense product range, also they are available including EVOH (3 or 5 layers).

It meets AENOR (Spain), SKZ (Germany), DIN CERTCO (Germany), IIP (Italy), KOMO (Netherlands) certifications, complaying with UNE-EN ISO 22391.

Advantages:

Easy Installation

No welding or mechanization required as the fittings system gives

simplicity and optimizes the costs.

Flexibility

Can be easily bent and curved in

cold without special tooling, saving unions and installation time.

Temperature resistance

Allowing temperatures up to 95°C and even 110°C for short periods.

Pressure resistance

The high density polyethylene provides more than 50 years lifetime

durability.

Resistant to corrosion

Suitable for corrosive fluids transportation.

Minimal pressure losses

Much lower roughness than metallic pipes reducing energetic consumption

and allowing a higher flow with the same internal pipe diameter.

No deposits

Layers very resistant to calcium, dirt and substances derived from

galvanic corrosion.

Lightness

It weights 7 times less than copper and 13 times less than iron on

equivalent diameters.

Excellent sanitary conditions

It does not modify the organoleptic characteristics of drinking water and

the corrosion absence avoid proliferation of bacteria.

Thermal, Electrical and Noise Insulator

Providing energy savings by reducing heat losses.

Frost resistance

It prevents condensation, reducing the freezing process.

Suitable for seismic zones

Because of its elasticity can absorb higher stress than metal pipes.

Thermal memory

Recovering the original shape when hot air is applied allowing to be

repaired.

Applications

- Plumbing installations.

- Underfloor heating systems

- Radiator heating installations

- Air conditioning installations

- Industrial installations (compressed air system, transport of toxic or

corrosive fluids …) - Ice/snow melting systems for public buildings or particulars

- Livestock facilities

PERT-AL-PERT

Mutilayer pipe

Our PERT-AI-PERT Multilayer pipe is composed by 5 layers using the butt welded system to deliver the highest quality and it is Certified by the most prestigious European Institutes (SKZ, AENOR) complying with the UNE-EN ISO 21003 European regulations and ISO 9001.

The combination of PE-RT and Aluminum provides excellent properties, obtaining the advantages of both materials: Plastic (flexibility, corrosion, low thermal conductivity) and Metal (low linear expansion, pressure, and temperature resistance) eliminating disadvantages.

Layers

PE-RT inner layer

Polyethylene with high temperature resistance, according to the regulation

UNE-EN ISO 21003.

Adhesive layer

Specially designed to paste plastic with metal, with a melting point

higher than 120ºC.

Special butt welded Aluminum alloy designed for pressurized water pipes

Perfect pipe symmetry for Fitting adjustment and major mechanical uniform

resistance to water pressure and bending stress (the welded point is the

strongest point of the aluminium layer).

PE-RT outer layer

Polyethylene with high temperature resistance, according to the standard

UNE-EN ISO 21003

DOWNLOAD PE-RT Product Characteristics

Klett PIPE

The Klett complement for PEX-a or PE-RT pipe with EVOH (3 or 5 layers) adjust a micro-hook and loop system, innovative and reliable combined with the excellent properties of cross-linked polyethylene. Provides greater ease of installation and repositioning without damaging the insulating functions of the panels.

Any pipe with Klett system is allowed to adjust the distances of the micro-hook and loop system and the diameter of the tape as well as the diameter and thickness of the pipe according to the client’s needs.

The hook system tape is self-adhesive polypropylene with micro hooks, to stick around PE pipes.

Applications

- Quick to fix with a single operation

- No need for tools or extra material to install

- Easy to replace pipes if necessary

- One person to install, reducing effective cost

- Hook and Loop demonstrates high mechanical performance

- Reliable solution that does not damage insulation boards

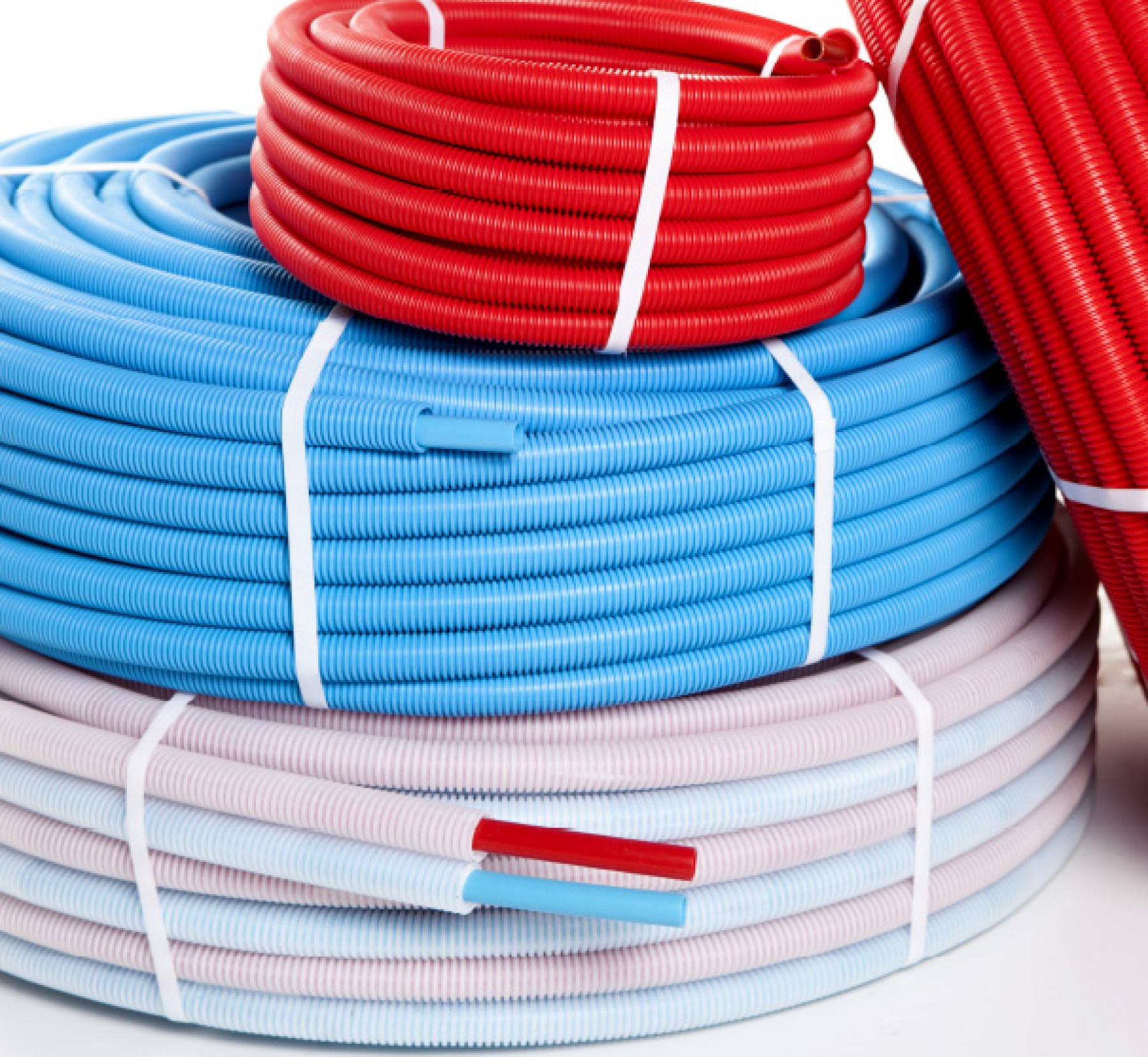

Corrugated pre-sleeved pipe

(Simple & DUO pipe in pipe)

We manufacture Simple & DUO Corrugated pre-sleeved pipes with multiple diameters according to CSTB standards. The Corrugated protects with a minimal resistance compression of 450N the PE-Xa and Multilayer PERT-Al-PERT pipe installations, allowing a fast and easy replacement on buried installations and differenciating hot and cold pipes.

| Pipe characteristics | Value | Standard |

|---|---|---|

| Density (23 °C) | 900 kg/m3 | ISO 1183 |

| Melt Flow Rate (230 °C/2,16 kg) | 1,3 g/10min | ISO 1133 |

| Melt Flow Rate (190 °C/5 kg) | 2,5 g/10min | ISO 1133 |

| Tensile Modulus | 1.300 MPa | ISO 527 |

| Tensile Strain at Yield (50 mm/min) | 8% | ISO 527 |

| Tensile Stress at Yield (50 mm/min) | 28 MPa | ISO 527 |

| Charpy Impact Strength, notched (23 °C) | 25 kJ/m² | ISO 179/1eA |

| Charpy Impact Strength, notched (-20 °C) | 5 kJ/m² | ISO 179/1eA |

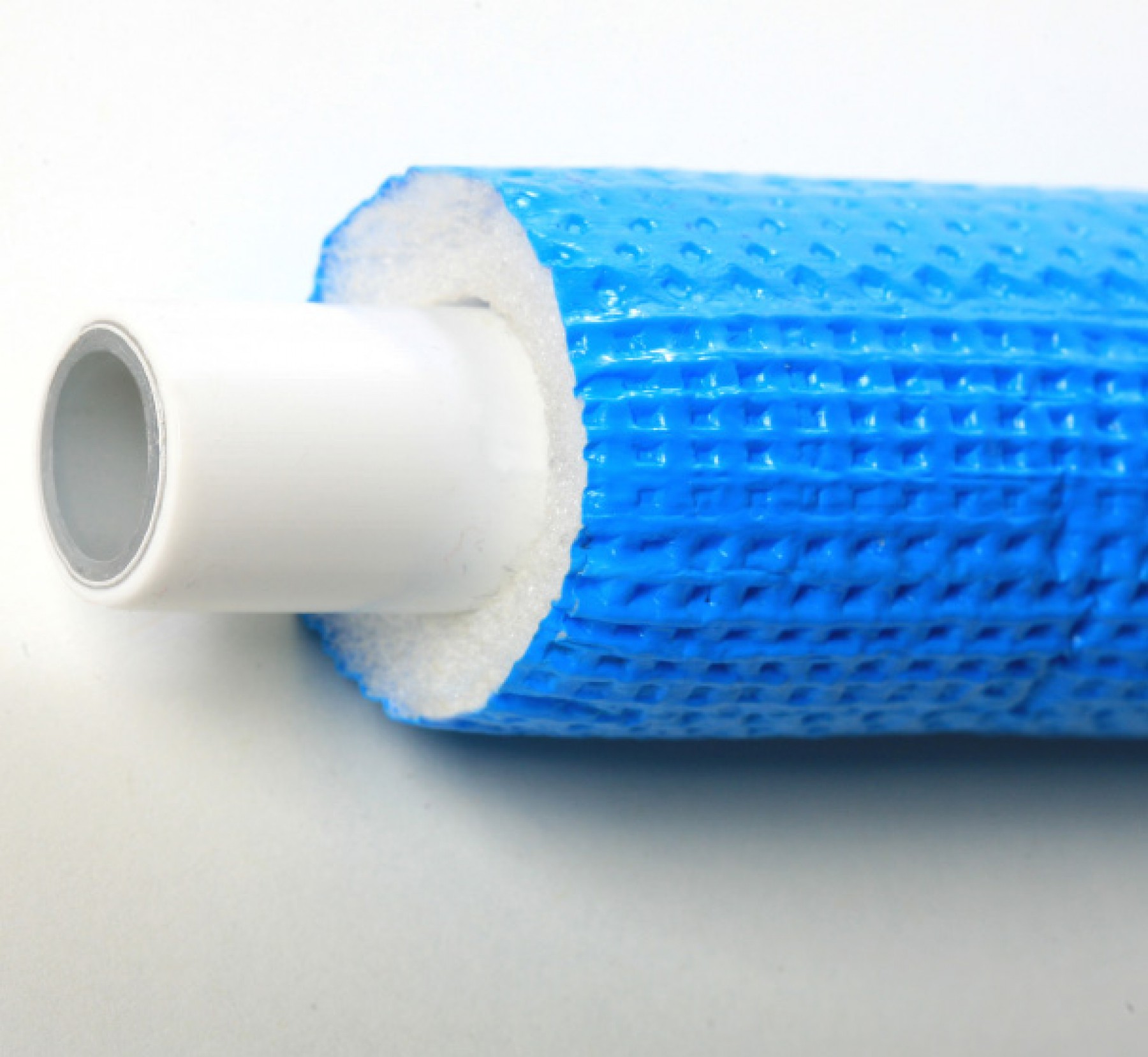

Pre-insulated pipe

We manufacture Pre-insulated pipes with multiple thicknesses and diamaters to optimize energy consumption, preventing future insullation installation costs and meeting the energy regulations.

The pre-insulated is a complement that completes the inner tube, providing thermal, sound and physical insulation capabilities, protecting the tube from external agents that can damage and hinder the proper functioning of the pipe.

Specially designed for

- PEX-a pipe.

- PERT

- PERT-AI-PERT pipe

- Corrugated pipe in pipe

PPSU Fittings

Having our own Fitting system we offer the most complete solution for sanitary water and heating plumbling installations. We offer a PPSU Fitting solution that enables to install with great ease, less time of installations, low level of technification and cheaper than other fittings madre from steel or copper materials.

We include measures from 12mm to 32mm and from 1/2″ to 1″.

Description

- No washer on fitting

- Using Pex-a, Pex-b, Pex-c and PE-RT pipes, suitable dimensions

- To use Multilayer pipes (with aluminum inside)

- Acctually no reduction of flow threw fitting

- Modern and resistible material

- Suitable price

- Low weight

- Easy and quick installation,

- For sanitary

- For classic heating/cooling systems

- For surface heating/cooling systems

- OEM solution